Anyone who has run a marathon, written a term paper for university or tried to learn a foreign language knows that speed alone does not lead to the desired goal. No matter in which area of life we move, to achieve good performance and lasting quality, a balanced combination of speed and persistence is necessary.

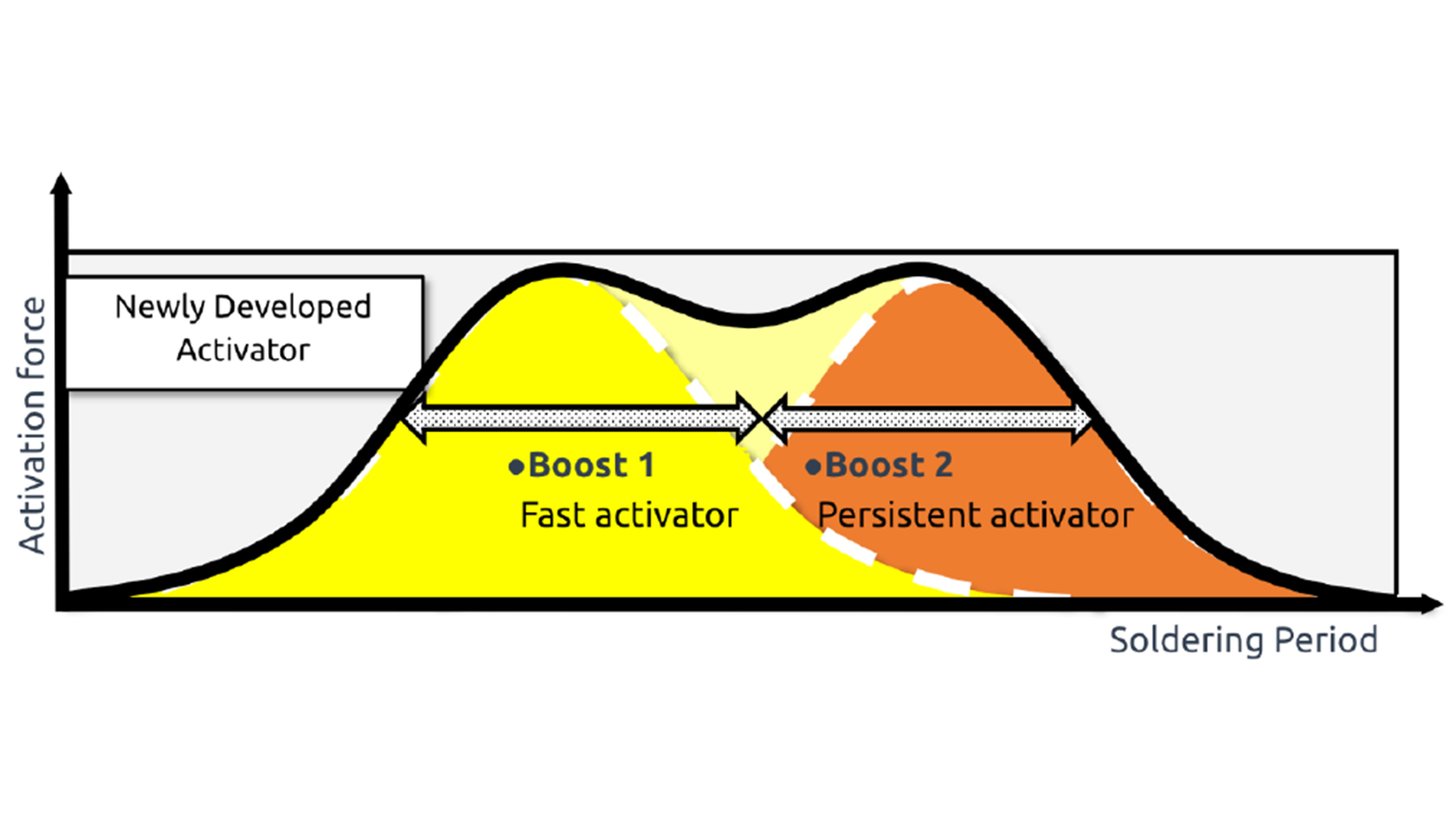

Almit's latest solder wire innovation DB-1 RMA LFM-48 M follows exactly this concept: with its dual boost of a fast and an persistent activator, this product achieves a new dimension in wettability.

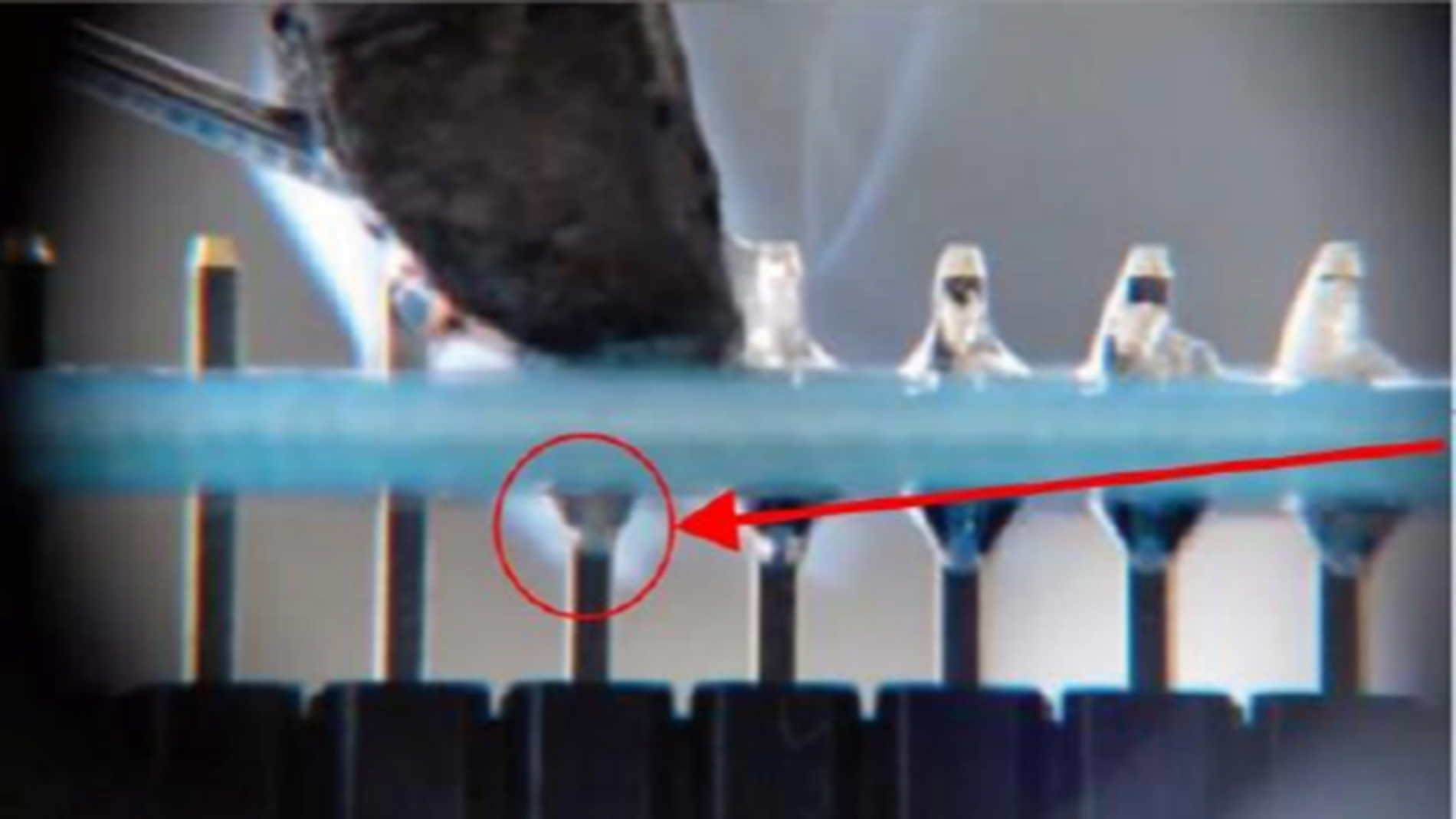

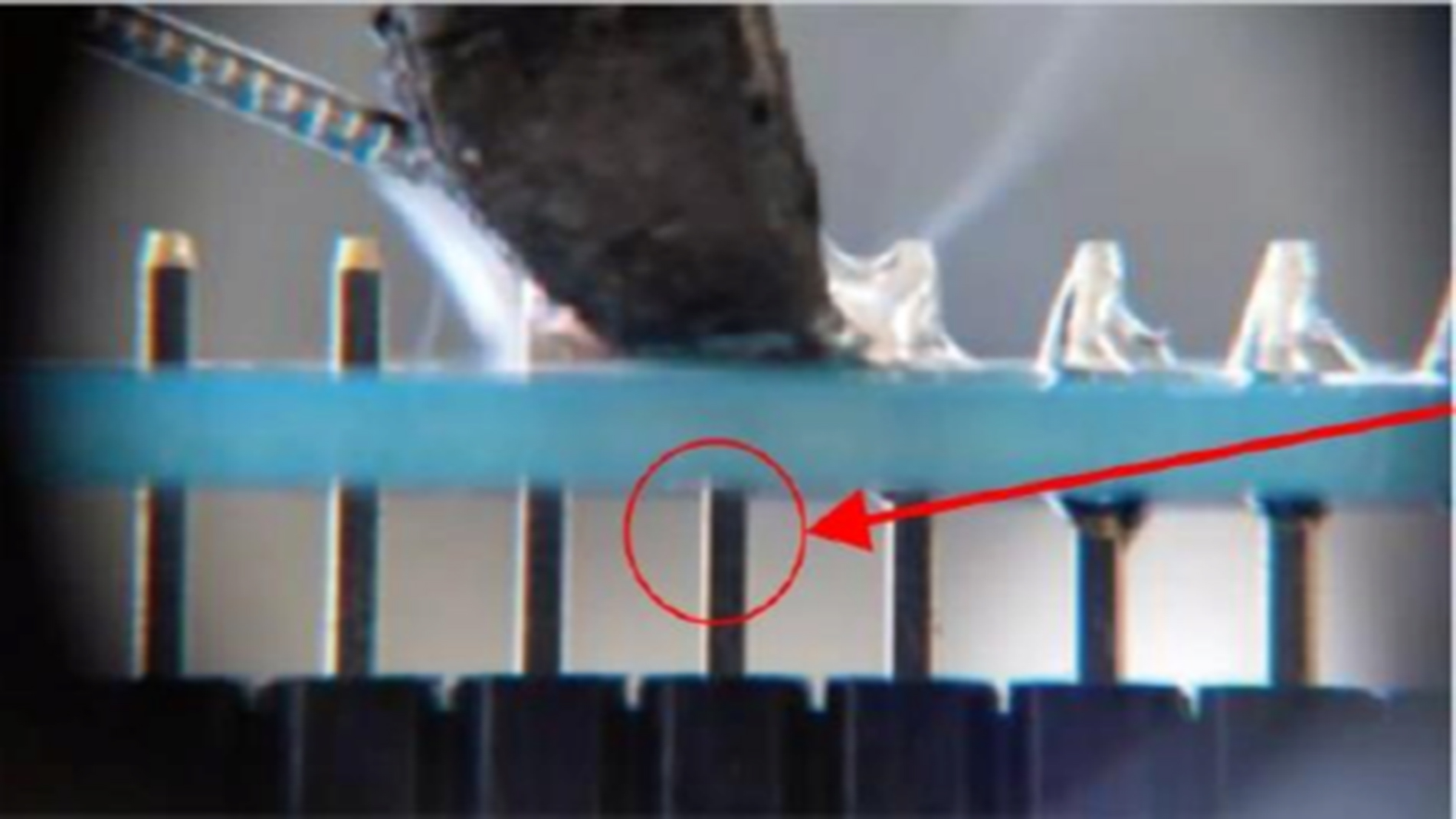

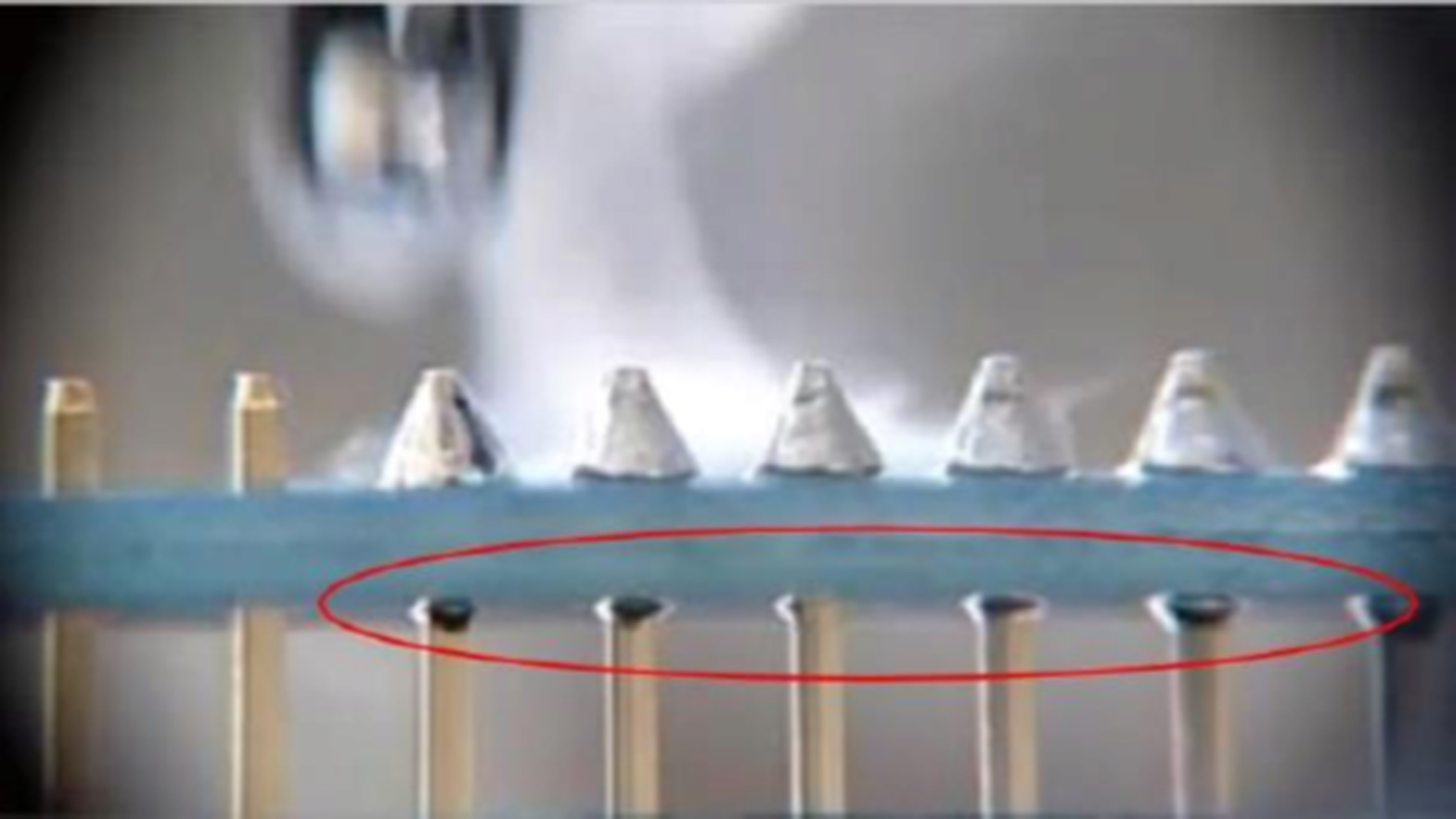

The double activation ensures excellent wettability. The first booster is a fast-acting activator that ensures good initial wetting. Due to its effect, the solder flows immediately into the through-hole. The second booster has a long-lasting effect and promotes through-hole wettability and the workability of the solder. In the product test, Almit's DB-1 RMA LFM-48 M is clearly ahead of a conventional solder wire, where the wetting is insufficient and the solder flows only with difficulty into the through-hole after reflow soldering.

Temperature of the soldering iron tip: 380°C; Speed of the soldering iron: 2mm/s

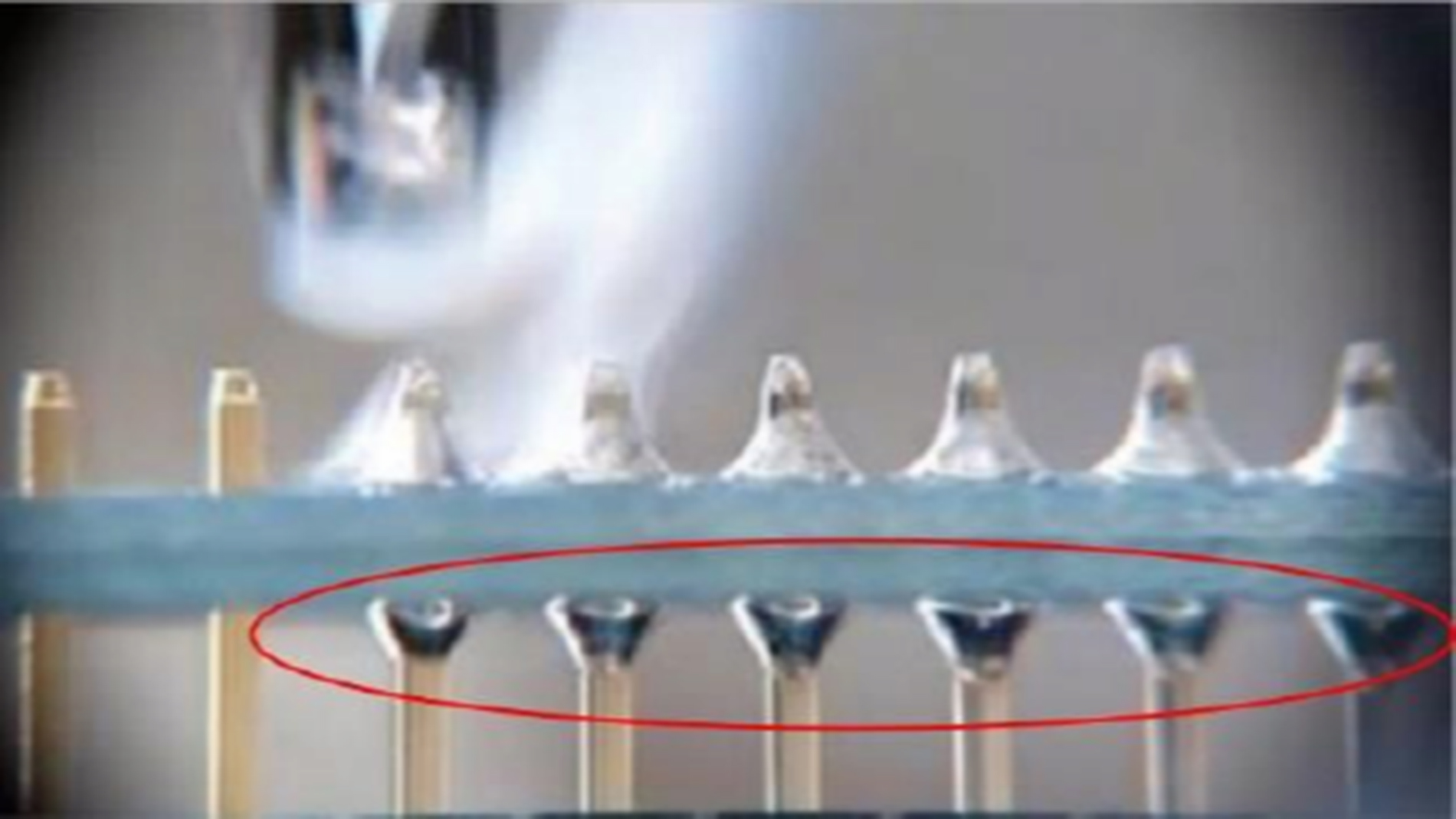

In addition, the persistent second booster favours the "anti-bridge effect", i.e. no bridges are created during drag soldering, which would lead to a short circuit when the PCB is used later.

The use of DB-1 RMA LFM-48 M can also be the solution for well-known "problem children", i.e. frequently occurring problems in the production process: For example, it enables a significant increase in solderability in through-hole soldering even with oxidised PCBs after reflow soldering. DB-1 RMA LFM-48 M also creates the prerequisite for achieving increased wettability of the through-holes and, as a result, increased solderability for PCBs with high heat capacities. With conventional solder wire, on the other hand, a much higher soldering temperature and a longer soldering time must be resorted to in these cases due to insufficient wetting in order to achieve a satisfactory result.

Temperature of the soldering iron tip: 380°C; Preheating: 0s; Feeding amount: 6mm

Feeding speed: 20mm/s

Reheating: 1.4, 1.0s

In addition to the significant increase in quality, DB-1 RMA LFM-48 M offers another advantage that is of crucial importance in the electronics manufacturing industry: the uniquely fast wetting behaviour enables a shortened process time and a long-term reduction in manufacturing costs. It is not only the flux that scores here, but also the alloy: The SAC alloy LFM-48 M convinces with a reduced iron alloying. The peak service life is increased and the peak consumption is reduced by 50 to 70 %.

With Almit's solder wire innovation DB-1 RMA LFM-48 M you get the double boost of speed and persistence to achieve even the most demanding production targets. For an outstanding soldering result that leaves nothing to be desired and a maximum reduction in working time, production costs as well as soldering tip consumption. Ready to discover a new dimension in wettability? Ask your Almit specialist!

DB-1 RMA LFM-48 M is available with the following product specifications:

| Flux |

Alloy |

Melting temperature |

Flux content |

Diameter (mm) |

|---|---|---|---|---|

| DB-1 RMA |

LFM-48M (Sn-3.0Ag-0.5Cu-α) |

217-221 centigrade |

3.5% |

0.3, 0.38, 0.5, 0.65, 0.8, 1.0, 1.2, 1.6 |

Tags

- Soldering