The flood of buzzwords bombarding us on a daily basis is not decreasing: everything is connected. And while everything is already considered to be “smart”, we are now being hit with artificial intelligence. Yet no matter whether we are speaking of Industry 4.0, IoT or IoP—they are all just applications. The core is and will be electronic hardware. It records measured values, data and statuses using various sensors and then stores, processes or transmits them.

Due to the large diversification of applications and their use as well as underlying business models, a large number of requirements must be implemented quickly and robustly. Moreover, manufacturers in other economies are under immense financial pressure. For most applications, a customer can search for suggested prices directly on the world's largest B2B/B2C trading platform and compare existing solutions with their own hardware. This puts considerable pressure on European electronic hardware manufacturers and developers to innovate. Not only the application itself must be future-proofed, but the complete supply chain and business model must stay profitable.

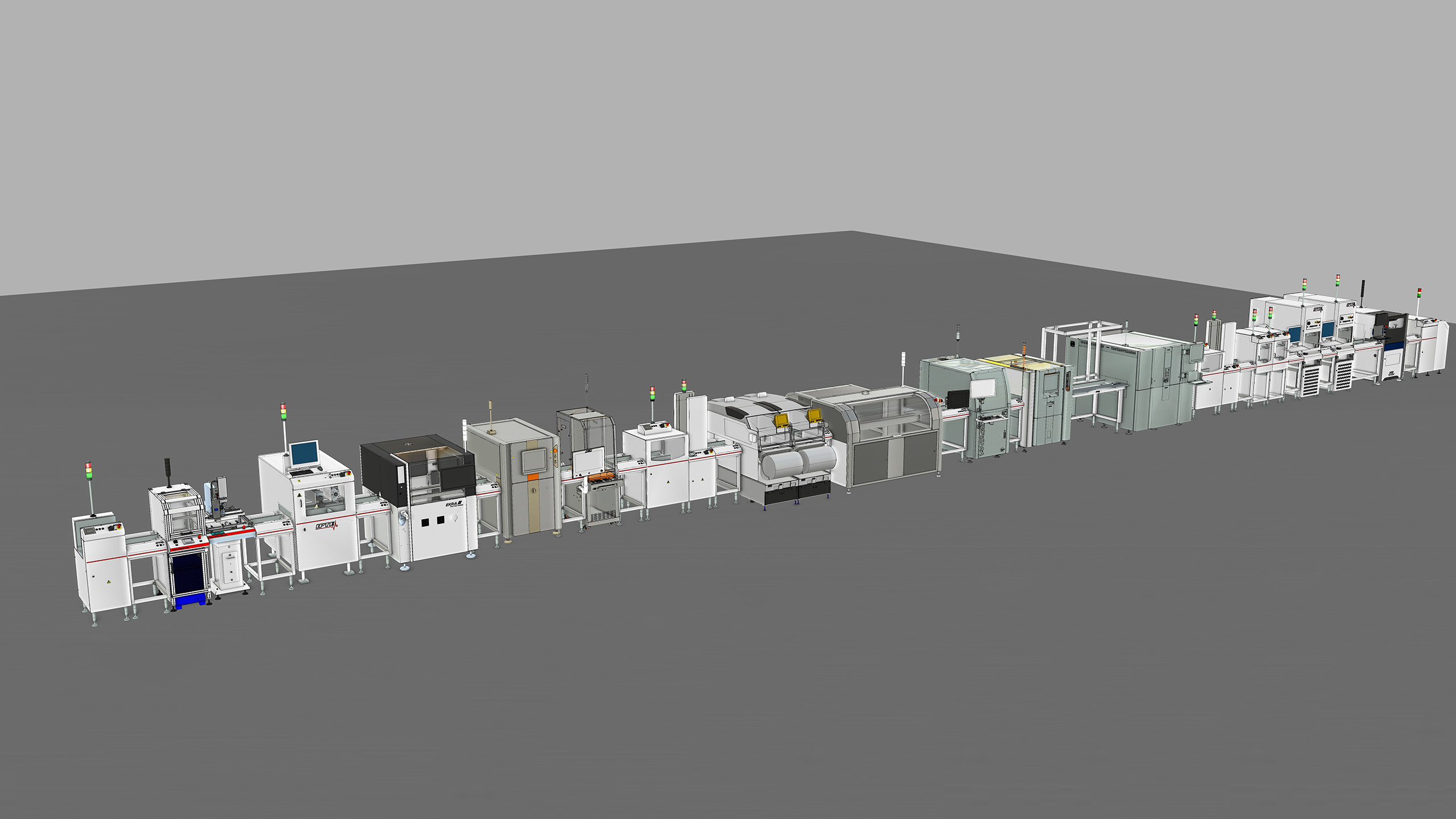

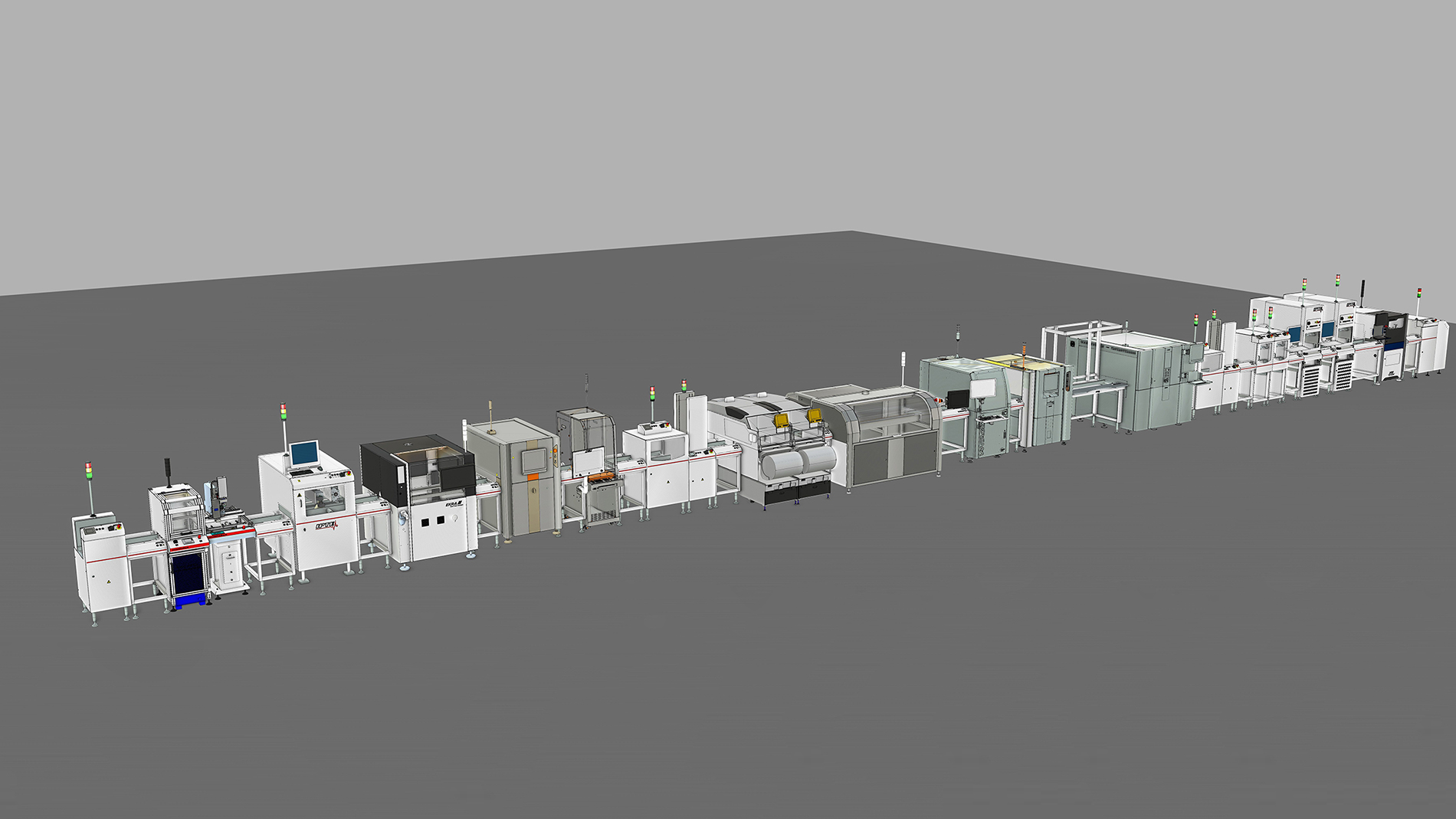

(Image: Fraunhofer IZM Berlin)

Questions that dominate our future also concern the general sustainability and recyclability of the manufactured assemblies. Development departments are spending an ever-greater proportion of resources on the issue of environmental compatibility and also on e.g. reuse or recycling possibilities.

These challenges facing the modern assembly production in the coming years are already part of the research and development projects at Fraunhofer IZM, which will again be responsible for planning and implementing the joint booth in 2019.

Ensuring the fastest possible set-up time and maximum flexibility remains high on the list. Implemented processes and technologies should be robust enough to be scaled to other production sites at any time without requiring expensive special equipment or materials. In recent years, the depth of inspection in particular has increased steadily as manufacturers are stepping up their software integration into their customers’ supply chain, and margins along the value chain are making zero-defect production nearly indispensable. The line itself will make it possible to demonstrate to visitors the different levels of data streams in a comprehensible and entertaining way through a complete M2M connection of all modules and an ERP system.

"How can a modern electronic manufacturer produce in the context of current trends and issues? This year's production line shows how.”

Related links

Tags

- Solutions

- Internet of Things (IoT)

- Manufacturing

- Industry 4.0