At the same time, the time spans between prototype development and series production are shortening – so all-round reliable inspection is increasingly required – even during start-up support. Measurability and compliance with specified limit values, process stability and audits are playing an ever more important role. In practice, some very specific questions arise: What actually needs to be measured and then documented? Which areas are of particular interest and which limit values should I specify? Depending on the assembly and component, the answer may vary. Decisive factors for the design of the process typically include the customer's specifications or the IPC-A-610 rules and regulations.

THT filling levels and void content in solder joints

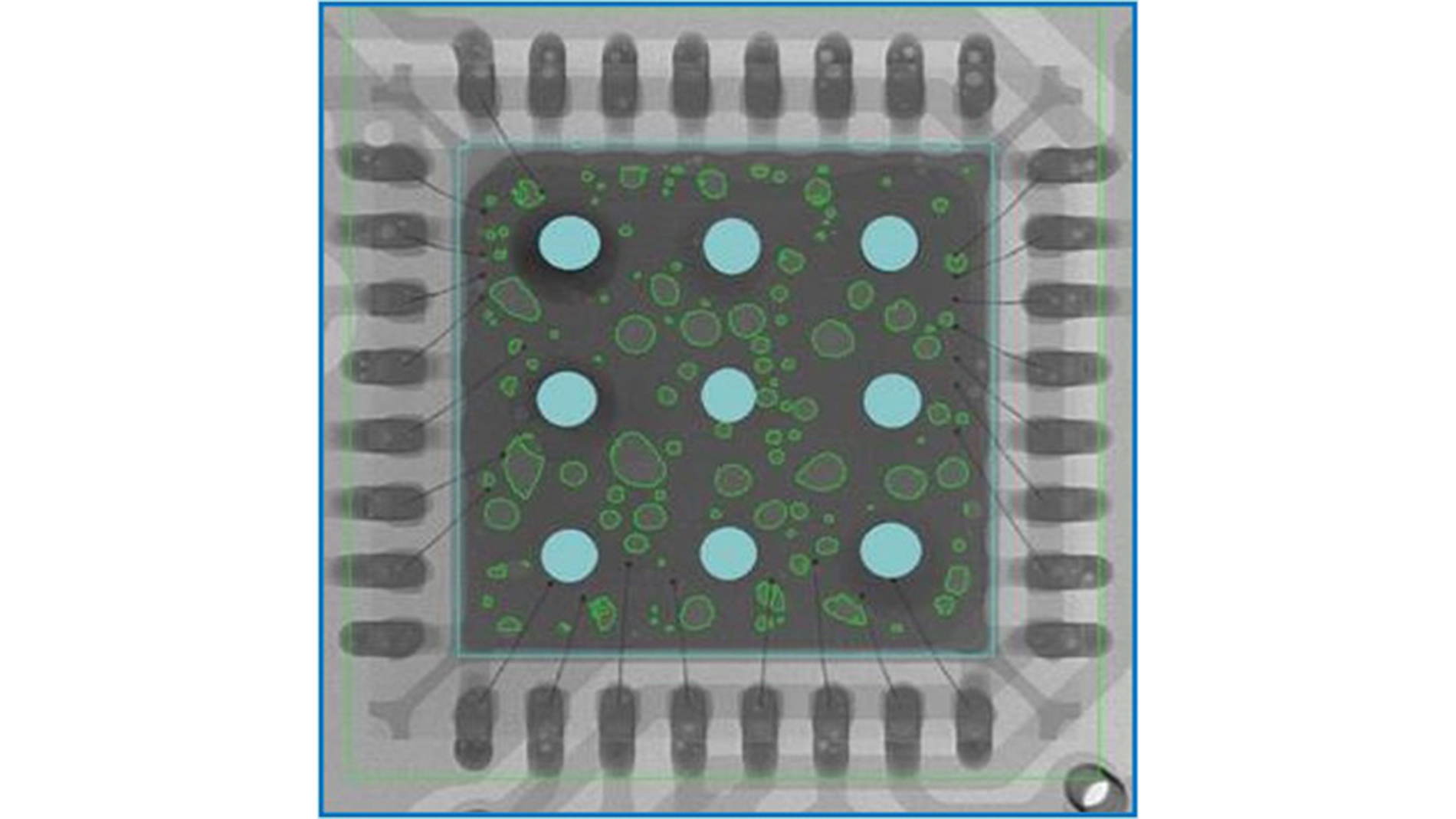

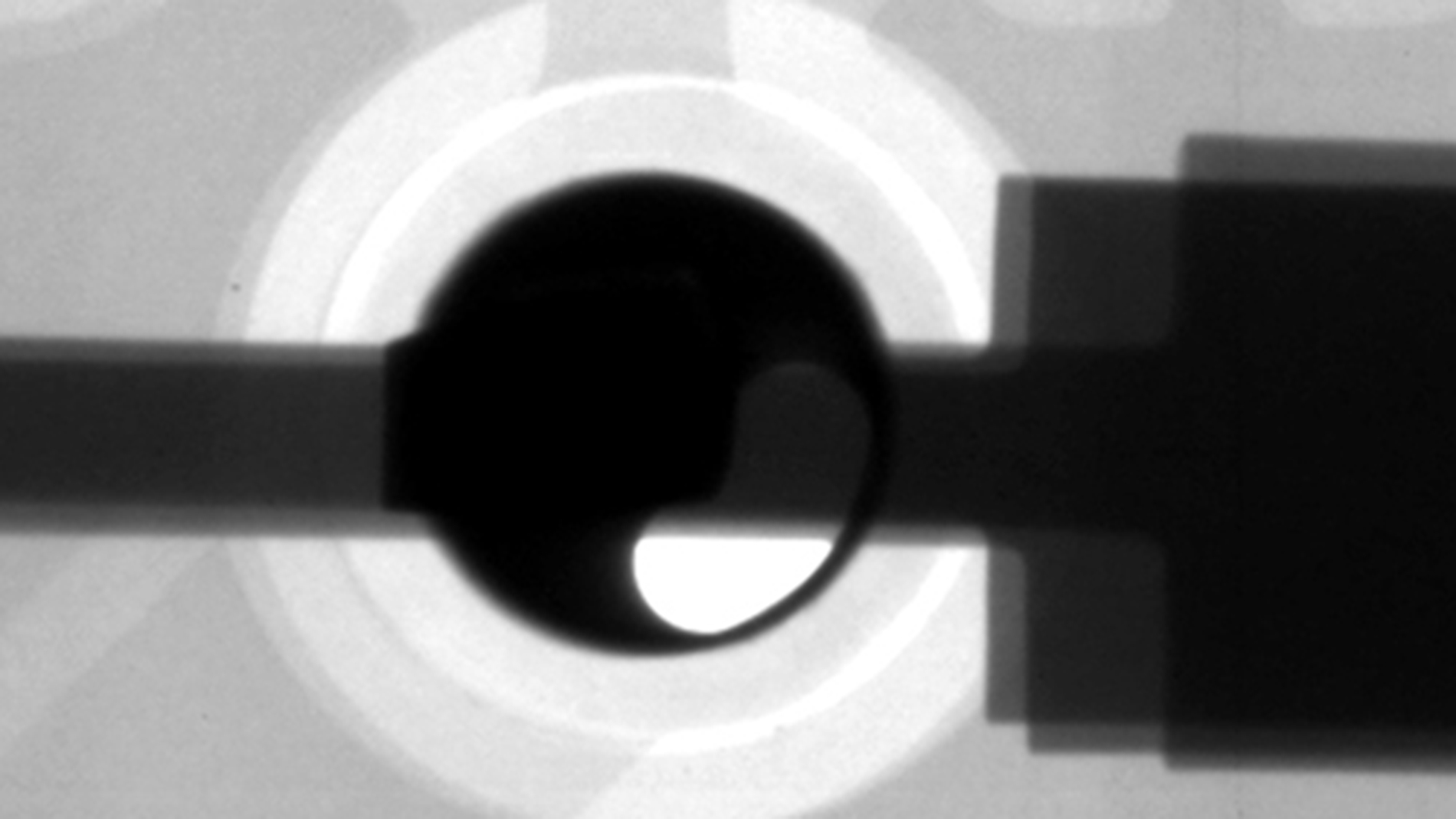

Very high accuracy of inspection results is clearly the foundation for reliable and transparent production processes. In the case of THTs, for example, 3D AXI can be used to precisely measure the filling level and thus ensure that the level does not fall below 75% of an optimum solder joint. However, the best-known example of measurements in the 3D-AXI range is still air/gas inclusions (voids) in the solder joints. If too much voiding is present, the long-term stability of a product can be jeopardized due to insufficient heat transfer. Not only in power electronics – where particularly high currents flow – can assemblies fail as a result. In many cases, production service providers for electronic components (EMS, Electronic Manufacturing Services) must therefore provide their customers with proof of 100% testing with regard to voids.

Ways to the right segmentation

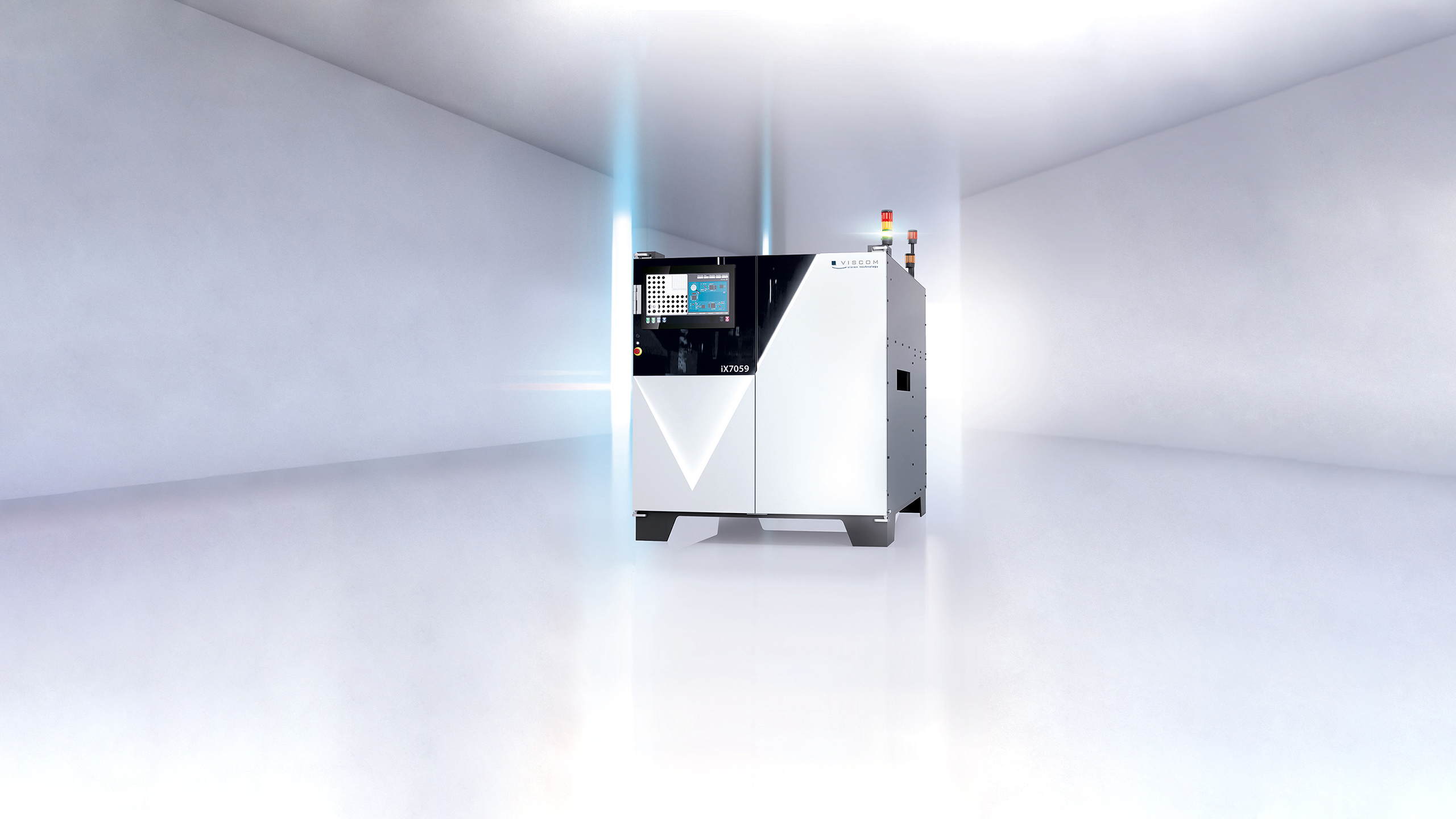

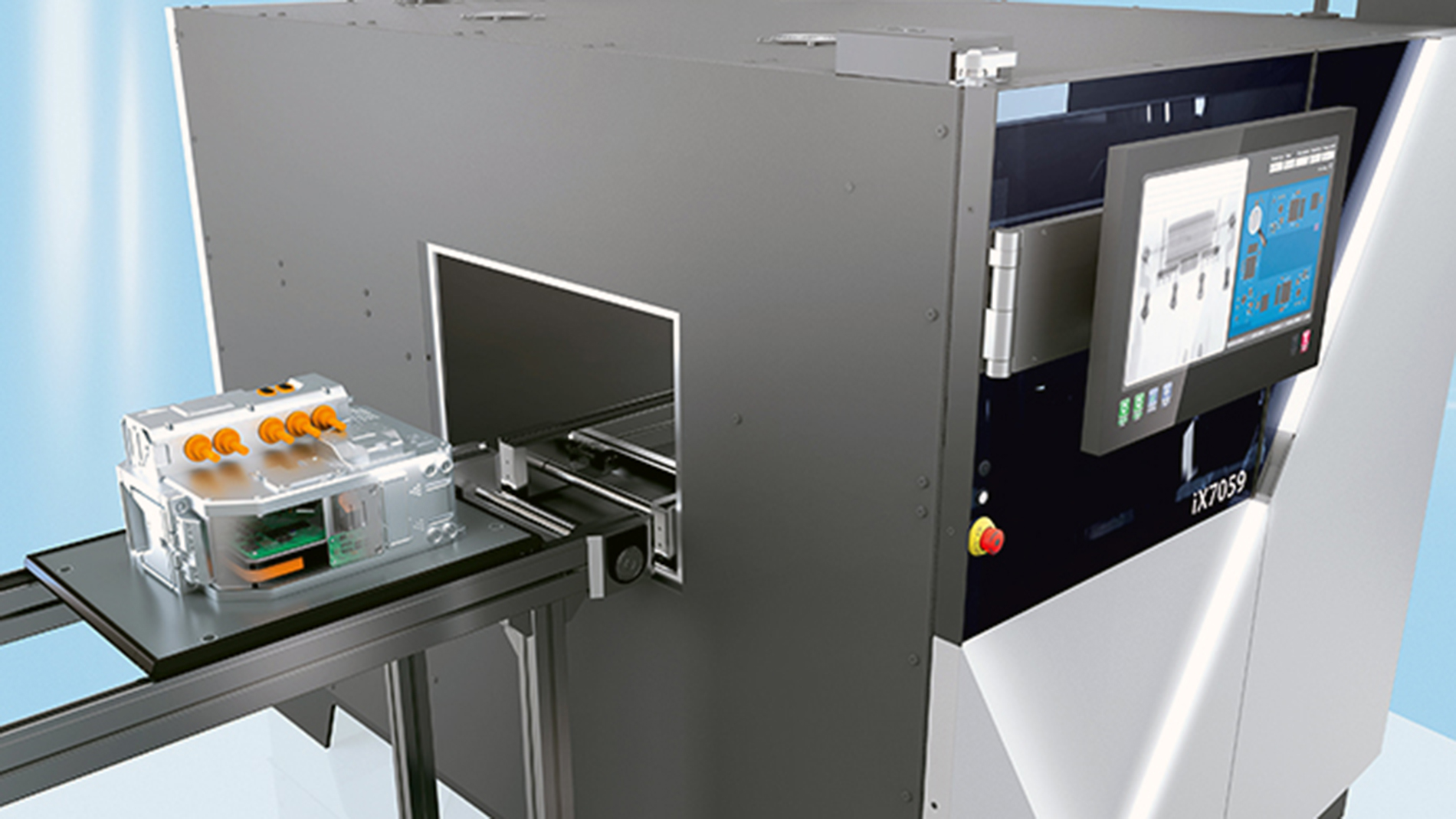

The demand for high-performance inspection systems for sophisticated quality assurance is correspondingly high. Inline X-ray offers great advantages, among other things, with its analyses from tomosynthesis. Individual slices from volume calculations show the desired results without shadowing. Defects are reliably detected in automated processes. To identify voids precisely, algorithms typically output the percentage ratio of the largest voids or all voids added together to a predefined total region. Among other things, it is important to select the reference value "100 percent" correctly when creating the test program. For example, do vias (direct contacting) in the solder area of a QFN count or not? Users must select one of the available options and then keep the setting consistent – with later comparability in mind. Artificial intelligence is also finding its way into this area more and more. Practice has already revealed really positive experiences with AI-supported segmentation when it comes to voids and their environment. The classifiers are continuously retrained in order to reliably recognize for each individual pixel whether it is a void pixel or not.

Proof of repeatable results

Whether in the future increasingly with the help of AI or other methods used today – once a defect has been identified, it is vitally important to consider it in its expression in comparison to other defects. Customers of a manufacturing service provider can therefore attach key importance to the repeatability of the results as an important quality requirement and check compliance with this specification via corresponding audits – also on a spot check basis for instance. Tests for the capability of measuring equipment are known from quality management under the abbreviation MSA for Measurement System Analysis. The accuracy achieved by a system is made up of criteria such as the correctness of the results and the repeatability. In contrast to systems for automatic optical inspection, this is not usually done with the aid of a certified target in inline X-ray inspection, but rather on the basis of assemblies from production that are repeatedly inspected – for instance 50 times under the same conditions. Even if MSA is not required, performing it on a rotational basis can be useful to test the reliability of ongoing inspection programs. In this context, it is of course also important that the systems undergo calibration at specified time intervals. Basically, this is nothing more than ensuring repeatability over months and years. This is also an important aspect in connection with audits – for example against the background of the IATF 16949 standard, which is important for quality management in the automotive industry, and the associated certifications. With a 3D AXI system, for example, gray scale calibration can be performed automatically in addition to continuous self-monitoring for hardware or system errors. In addition, appropriate calibration bodies are used to ensure metrological traceability.

Solid foundation of image information

The stability of processes can also still be checked in a somewhat traditional way with the aid of "image bases". Databases created by operators and maintained over the long term with images of real and boundary defects as well as good examples from production can serve as reliable process indicators even in the case of minor changes such as the use of a new solder paste. Once labeled, the verification data is available as important empirical data for future optimization of inspection programs. If the inspection results are also backed up by statistical evaluations based on comprehensive process control, nothing stands in the way of audit-proof inline X-ray in a modern production line. Ideally, all inspection gates from solder paste inspection (3D SPI) to optical post-reflow inspection (3D AOI) to inline and offline X-ray (3D AXI and 3D MXI) are fully networked with each other and a combination of their data is available for all required purposes.

Tags

- Test and inspection solutions (AOI, AXI, ICT)

- PCB