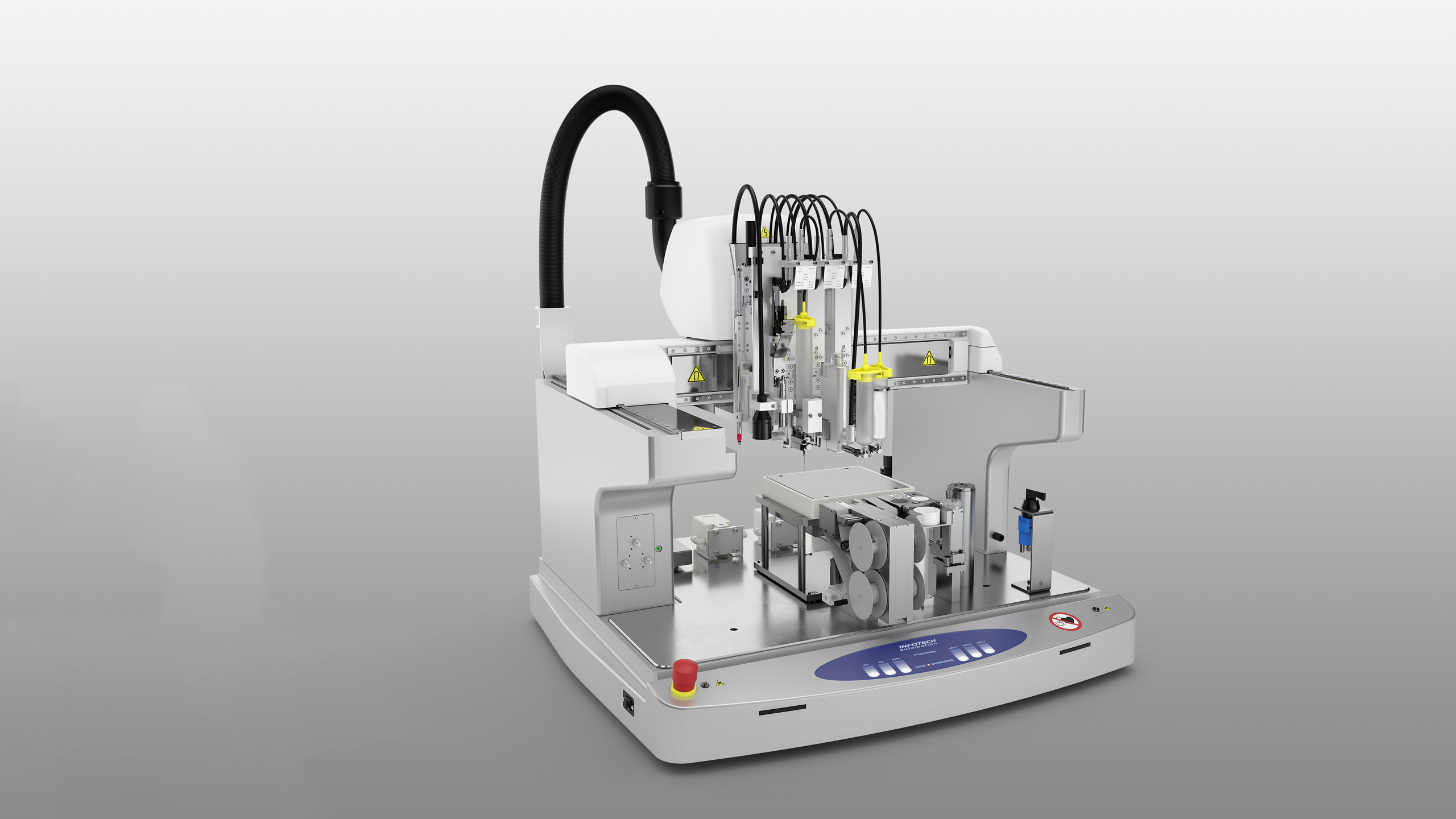

The core of the new system is a special dispensing unit that can be equipped with up to three different dispensing valves. Depending on the properties of the pressure media and the structures to be dispensed, users can choose from a variety of established dispensing valves, such as jet valves, time-pressure valves, or screw dispensing systems. Each valve sits on a separate vertical axis. Since the dispensing heads can be operated in parallel, it is possible to combine different liquid materials in one printing process. Linear axes and integrated real-time control ensure maximum dispensing precision. The segmentation of the structure and the segments' allocation to the different dispensing valves are stored in the STL model and correctly implemented in the dispensing pattern by the slicer software. A camera moving along with the robot head detects the exact dispensing position and at the same time is used to calibrate the dispensing system.

Reliable Printing of Functional Structures

To produce multi-material designs, it is not only the system's precision that is crucial, but also the materials used. During the printing process on the Infotech system, the materials are applied in liquid form and then cure under UV light. The effective thickness of the applied layer is determined by a non-contact height measurement. This allows the working distances of the dispensing units to be dynamically corrected if necessary. For curing, the UV lamp head mounted in the system travels along the contour dispensed last. The material thus immediately reaches its final strength.

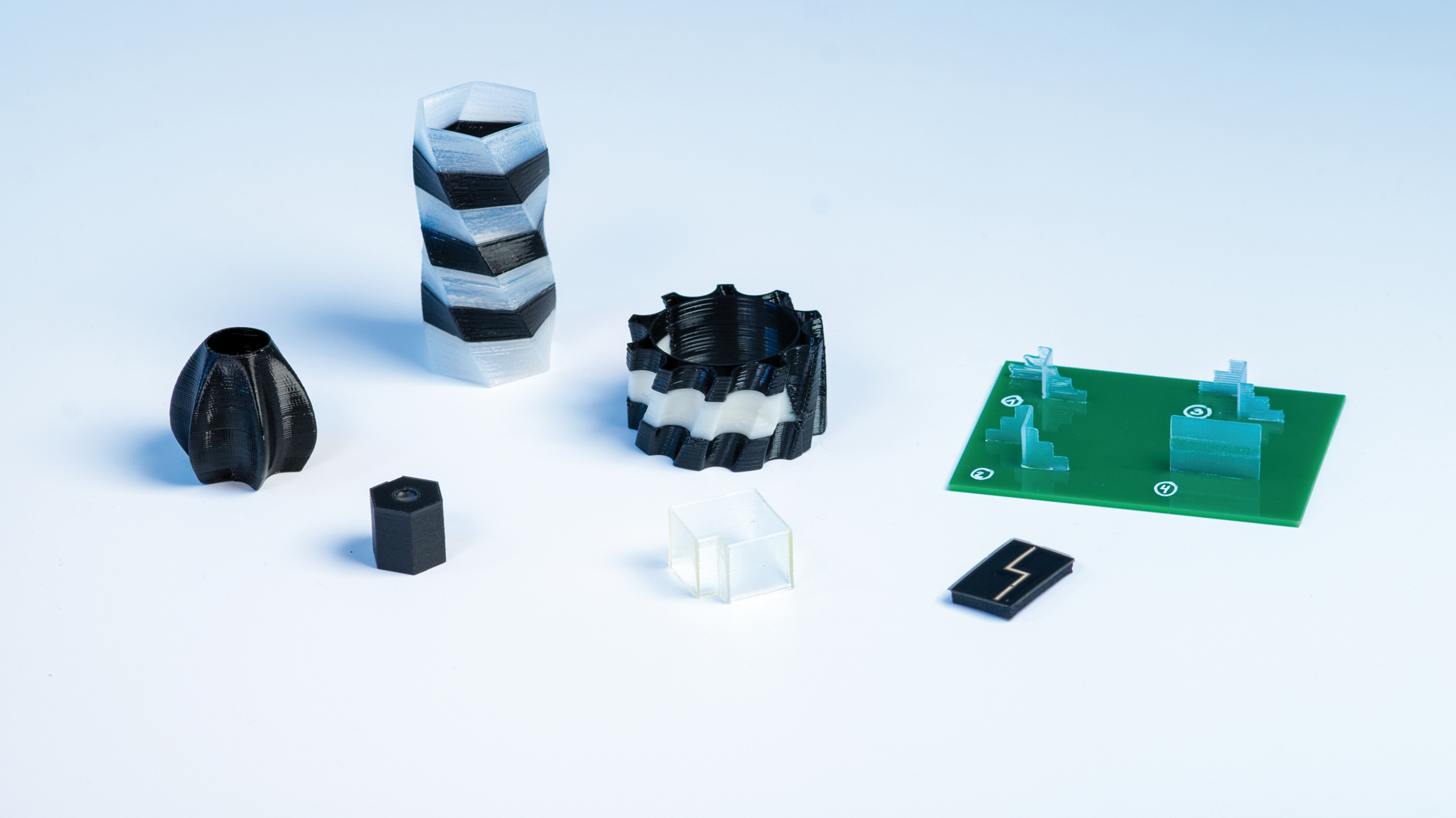

The distinctive feature e.g. of DELO's liquid materials is their suitability for combination and their functional character. Having similar chemical properties, the printing materials build up very good adhesion to each other and show isotropic properties in all printing directions when cured. In addition, they provide functions such as transparency, conductivity, or flexibility (fig. 1).

The DELO materials can be used to reliably print components serving different functions – for example, components with fixed and flexible areas or with transparent and black areas. Structures with wall thicknesses of less than 500 µm can be produced just as easily as complex structures with overhangs or undercuts.

Process reliability

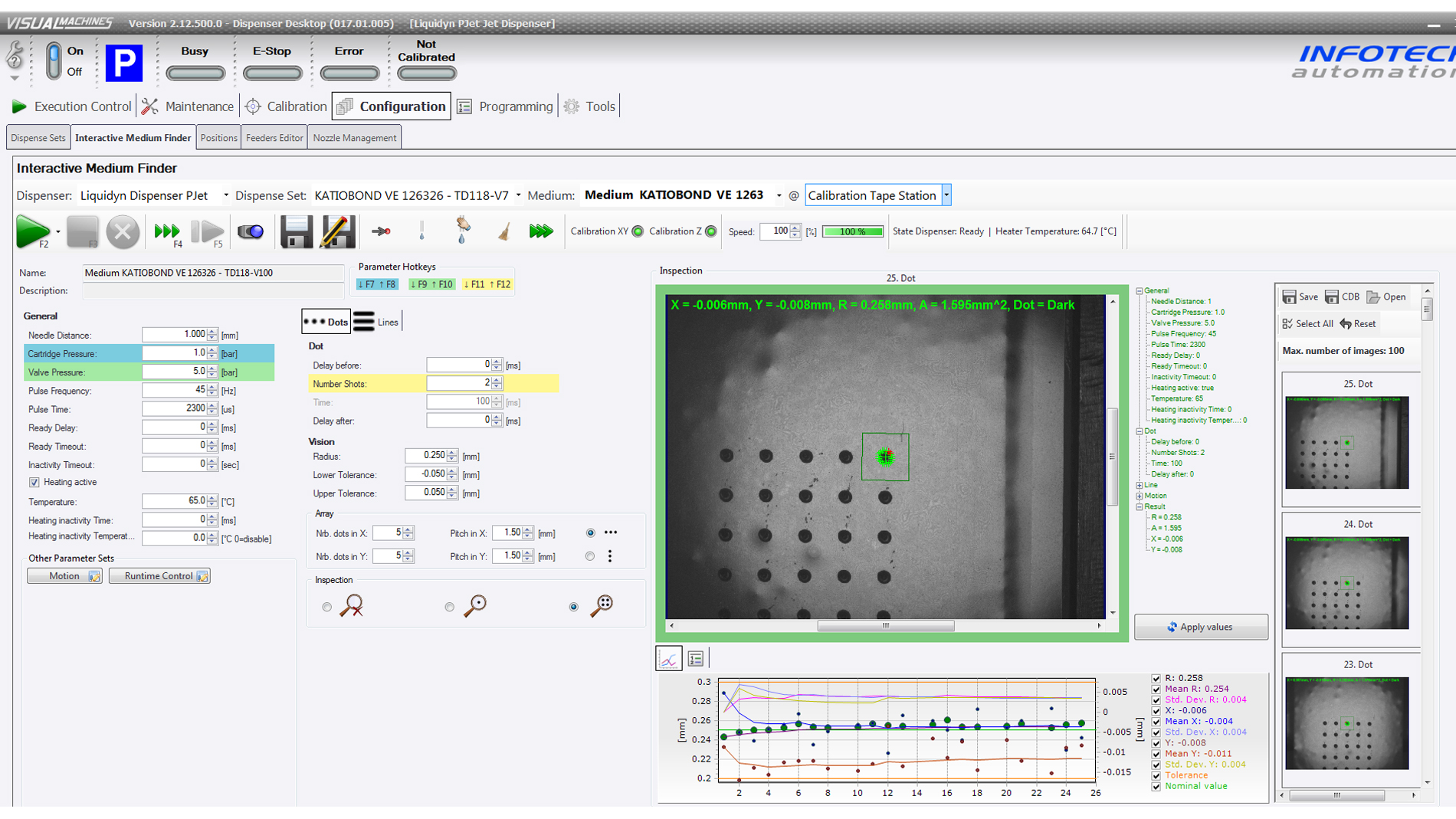

To ensure that a running print job is not aborted due to process fluctuations, various tools ensure process reliability. Both the hardware and software of the system have process monitoring functions. The dispensing result can also be determined by checking the dot or line size, among other criteria. The results can be saved as a log file or further processed using traceability software. The connection to a line computer is available as an option. The Interactive Media Finder is a timesaving, efficient and intuitive helper, especially for process development. Parameters can be changed during live dispensing, which has an immediate effect on the result and can be observed and measured. Once the optimum parameters have been found, they can be stored in the database for its use in application programs (fig. 2).

In addition, the system offers the feature of viscosity compensation based on the measured dispense results, such as droplet diameter or weight of the material dispensed onto an integrated analytical weight scale. The corresponding dispense parameters are then adjusted automatically. Usually, one of the dispense parameters to be adjusted can be selected in the parameter set. For example, in the case of an electropneumatic jet valve, this can be the cartridge pressure or the frequency. The viscosity compensation function ensures the balancing of the chemically induced viscosity fluctuations of printing materials and thus also ensures a precise printing result. Fully automatic and integrable into production lines.

The entire dispensing and curing process is fully automatic, as is the cleaning of dispensing needles or flat nozzles. Cleaning can be carried out as required, either after a certain number of cycles or components or after a defined period. The new system, which was developed based on the proven IP-500 Desktop Dispenser, can be used as a standalone system. The identical machine configuration can be easily integrated into in-line dispensing cells. The system is particularly suitable for prototype development and small-series production. Typical areas of application for such components printed with DELO materials include the automotive and microelectronics industries, as the materials are highly resistant to temperature and media and have properties similar to those of high-performance plastics.

Fig. 2

Fully automatic and integrable into production lines

The entire dispensing and curing process is fully automatic, as is the cleaning of dispensing needles or flat nozzles. Cleaning can be carried out as required, either after a certain number of cycles or components or after a defined period. The new system, which was developed based on the proven IP-500 Desktop Dispenser, can be used as a standalone system. The identical machine configuration can be easily integrated into in-line dispensing cells. The system is particularly suitable for prototype development and small-series production. Typical areas of application for such components printed with DELO materials include the automotive and microelectronics industries, as the materials are highly resistant to temperature and media and have properties similar to those of high-performance plastics.

Publishing date

25 August 2021

Related links

Tags

- Dosing techniques

- Automation solutions